Call Us Now

+8615914489090

With the continuous advancement of the country's new infrastructure and digital economy, the Industrial Internet of Things is increasingly appearing in people's vision. According to statistics, the market size of China's industrial IoT industry will exceed 800 billion yuan in 2021, reaching 806 billion yuan.According to the national planning goals and the current development trend of China's industrial Internet of Things, the scale of my country's industrial Internet of Things industry will further increase in the future, and the growth rate of the industry market scale will gradually increase. It is estimated that the market size of China's industrial Internet of Things industry will exceed one trillion yuan by 2023, and it is predicted that the market size of China's industrial Internet industry will grow to the level of 1.25 trillion yuan in 2024. The prospects of my country's industrial Internet industry are very optimistic.

Chinese enterprises have launched many industrial IoT application practices. For example, Huawei's "digital oil and gas pipeline" can effectively help managers understand pipeline operation dynamics in real time and reduce operation, maintenance and management costs; Shanghai Electric Power Company introduced IoT technology into warehouse management and built the first unattended warehouse in the system. Improve the level of material management...

It is worth noting that although nearly 60% of the interviewed Chinese business executives said they had formulated an IoT development strategy, only 40% said they had made related investments. This may be related to the fact that the initial investment of the Industrial Internet of Things is relatively large, and the actual effect is unknown. Therefore, today I will talk about how the Industrial Internet of Things can help factories reduce costs and increase efficiency with the actual case of the intelligent transformation of air compressor rooms.

Traditional air compressor station:

High labor cost, high energy consumption cost, low equipment efficiency, and untimely data management

Air compressors are air compressors, which can produce high-pressure air for some industrial equipment that requires high-pressure air of 0.4-1.0MPa, such as cleaning machines, various pneumatic measuring instruments, etc. The power consumption of the air compressor system accounts for about 8-10% of the industrial energy consumption. The national air compressor power consumption is about 226 billion kW h/a, of which the effective energy consumption only accounts for 66%, and the remaining 34% of the energy (about 768.4 100 million kW•h/a) was wasted. The shortcomings of traditional air compressor rooms can be summarized as follows:

1. High labor cost

A traditional air compressor station consists of N compressors. The start, stop, and status monitoring of the air compressor in the air compressor station depend on the management of the on-duty personnel in the air compressor station, and the cost of human resources is high.

Moreover, in the maintenance management, if the method of manual regular maintenance and on-site inspection is used to check the air compressor after the event, it is time-consuming and laborious, and there is a lag in the troubleshooting after the event, which hinders the use of production and causes economic losses. In the event of equipment failure, over-reliance on equipment service providers will result in delays in production and waste of time and money.

2. High energy consumption cost

When the manual is on duty, the actual gas demand at the end is unknown. In order to ensure gas consumption, more air compressors are usually turned on. However, there are fluctuations in the gas demand at the end. When the gas consumption is small, the equipment will be idling, or the pressure will be forced to release, resulting in waste of energy consumption.

In addition, manual meter reading has poor timeliness and poor accuracy, and there is no data analysis. Pipe leakage occurs, and the pressure loss of the dryer is too large, which wastes time and cannot be judged.

3. Low equipment efficiency

In the case of single unit operation, the production demand can be met by starting on demand to achieve constant gas consumption. However, in the case of multiple units in parallel, there are situations in which the size and power of the equipment are different, and the gas consumption and gas consumption period of different production workshops are inconsistent. The station scientifically dispatches on-off machines, meter reading, energy saving, and power loss put forward higher requirements.

Without reasonable and scientific collocation and planning, the expected energy-saving effect cannot be achieved: For example, the use of post-processing equipment such as first-class energy-efficiency air compressors and refrigeration dryers, but the energy-saving effect after operation cannot meet expectations.

4. Data management is not timely

It is time-consuming and laborious to rely on equipment managers to manually count gas and electricity consumption reports, and there is a certain lag, and business operators cannot make management decisions based on electricity consumption and gas production reports in a timely manner. For example, there is a data lag in the data report of the day, week, and month, and each workshop needs to be independently calculated, the data is not unified, and the meter reading is inconvenient.

Digital air compressor station system:

Avoid personnel waste, intelligent management of equipment, real-time data analysis

After the professional company transforms the station building, the air compressor station will become digitalized and intelligent. Its advantages can be summarized as follows:

1. Avoid wasting personnel

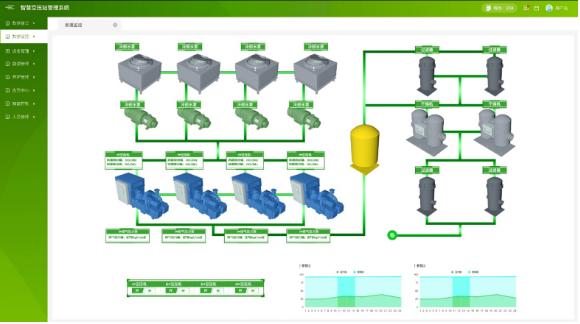

Station building visualization: 100% restore the overall situation of the air compressor station through configuration, including but not limited to real-time data monitoring and real-time abnormal alarms of air compressors, dryers, filters, valves, dew point meters, electricity meters, flow meters and other equipment , to achieve unmanned management of equipment.

Various required parameters of the air compressor will be displayed in real time in numbers

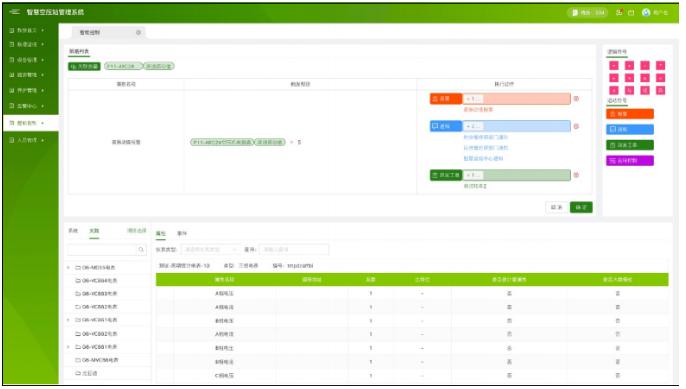

Planned configuration: Automatically start and stop the equipment by setting the planned time, ensure gas consumption according to the plan, and eliminate the need for personnel to perform the start-up operation on site.

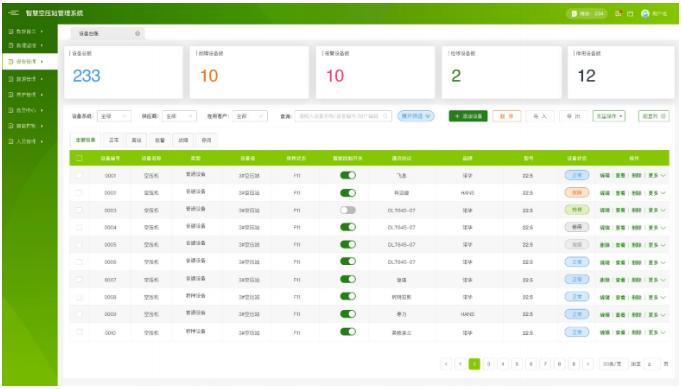

2. Device intelligent management

Timely maintenance: Customize maintenance reminder time, the system will calculate and remind maintenance items based on the last maintenance time and equipment running time. Timely maintenance, reasonable selection of maintenance items, and avoid excessive maintenance.

Intelligent control: Through precise strategies, the equipment is reasonably controlled to avoid waste of energy consumption. It also has a certain protective effect on the life of the equipment itself.

3. Real-time data analysis

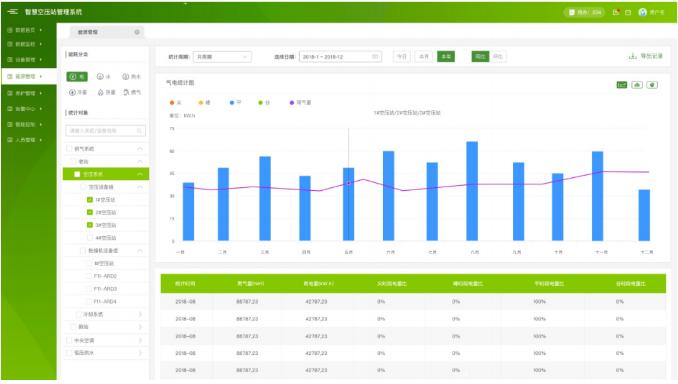

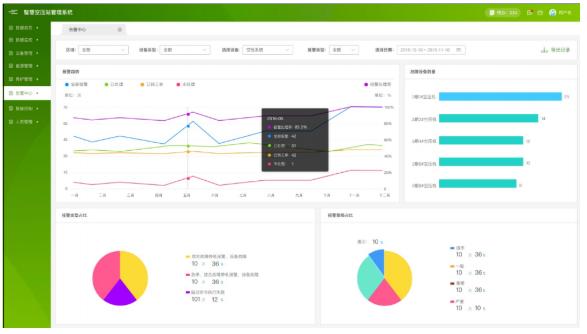

Data perception: The home page can directly see the gas-to-electricity ratio and unit energy consumption of the station building.

Data overview: View detailed parameters of any device with one click.

History traceability: All parameters can view historical parameters according to the granularity of year, month, day, hour, minute and second, and have corresponding graphs, which support one-click export of tables.

Energy management: dig deep into the abnormal points of equipment energy consumption, and improve the equipment efficiency to the best.

Analysis report: Combining operation and maintenance, control, and operation effectiveness to obtain the same analysis report and analysis and optimization plan

In addition, the system also has an alarm center, which can record historical failures, analyze the causes of failures, locate problems, and eliminate hidden dangers.

All in all, this system will make the air compressor station work more safely and efficiently, and most importantly, it will also reduce costs and increase efficiency. Through the detected real-time data, different actions will be automatically triggered, such as controlling the number of operating air compressors and ensuring the low-pressure operation of the air compressors to avoid waste of energy consumption. It is understood that after a large factory used this system, although several million were invested in the early stage for transformation, the cost saved in one year was "returned", and after that, several million will continue to be saved every year. Such investment Buffett Looking a little excited.