Call Us Now

+8615914489090

Driven by the global digital wave, the Internet of Things industry is in a stage of vigorous development. As one of the key wireless data collection methods, the popularity of RFID technology in all walks of life is rapidly increasing. According to the global market research data of the RAIN Alliance, the sales of RAIN RFID tag and reader technology will continue to grow rapidly in 2020, and the global sales of ICs have increased from about 18 billion in 2019 to 21 billion.

As the popularity of RFID applications continues to increase, this growth momentum will continue to rise.

Industrial digitalization brings huge market increment, and the importance of RFID testing is becoming more and more prominent From the perspective of the market, with the rapid expansion of RFID in major application areas, on the one hand, the demand for RFID has increased significantly, and on the other hand, it has also put forward new challenges to the performance requirements of RFID. In this process, problems such as industry standardization and lack of standard formulation have been continuously exposed.

In the past, many companies were too rude in RFID testing methods, and generally only invested in testing equipment for some emergency projects. However, if the test effort is not enough in the early stage of the project, it is likely to cause problems such as low reading rate and signal interference in the follow-up, and even directly affect the success or failure of the project.

In recent years, with the substantial increase in the amount of RFID electronic tags, both enterprises and customers have higher requirements for the quality of electronic tags, and continue to increase investment in testing. Even many label R&D and production companies have set up their own laboratories. With the improvement of related functional requirements, the chain of test equipment has become more and more complete.

With the increasing application of RFID technology in retail, footwear, logistics, books, aviation baggage traceability and other fields, the application environment of RFID systems is becoming increasingly complex. In the actual application of RFID projects, the preliminary testing mainly lies in the selection of hardware and the testing of the application environment. In order to better implement the project, most practitioners will refer to the experience of similar projects in the past.

Cheng Mingming, general manager of Juxin Internet of Things Lab (Shenzhen) Co., Ltd., told reporters that from the actual situation, there are basically no projects that can be replicated. Any new application project is a big challenge, from the design of RFID electronic tags, the selection of rfid readers, the matching of middleware, and the test for each product will affect the results of the project.

No matter which field it is applied to, every project has a corresponding application scenario. At the same time, many projects do not have the conditions to test at any time, especially some foreign projects. However, in actual testing, the first choice must be to go to the application site to test.

Cheng Mingming said that for some projects that are limited in time and space, the application environment can be built in proportion by setting up scenarios to achieve the best cost performance while ensuring the test results. In addition, Juxin Internet of Things will also provide an environment for some node testing, such as warehouse storage, luggage sorting, clothing inventory, NFC anti-counterfeiting, and so on.

In the early stage of project implementation, all influencing factors must be considered, taking the most common clothing industry as an example. It is necessary to consider the material of the clothes, the material of the accessories, the quantity in the original packaging, the circulation process of the label data, and so on.

In addition, when the same RFID tag is applied to different scenarios, its reliability test requirements are different. For disposable labels, the shear force value can be lowered; for labels used in flat environments, the bending strength can be reduced; in addition, the temperature, humidity, light intensity, acid and alkali of the application environment should also be considered And so on, as well as the applicability test of the hardware, so that it can play the best effect in the project.

The original intention remains unchanged: Promote the standardization of electronic label testing

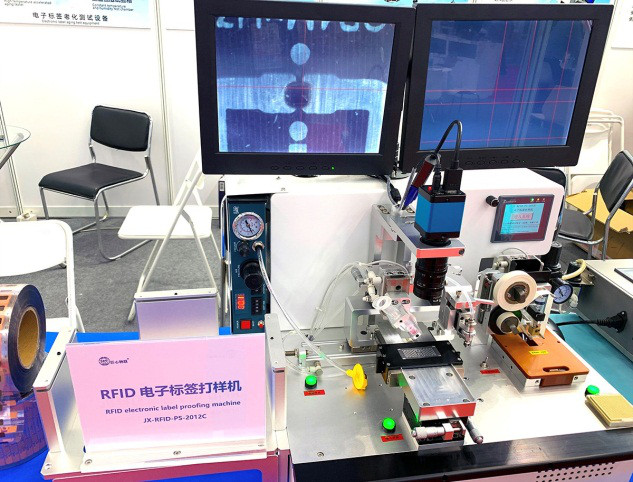

At the IOTE 2021 International Internet of Things Exhibition on October 23-25, 2021, Juxin Internet of Things Lab displayed the latest results, which attracted a large number of onlookers and inquiries from the audience.

Cheng Mingming said that at this year's IOTE exhibition, Juxin IoT will focus on testing equipment. The company has upgraded and optimized the shear force equipment to enhance the visualization function; and the electronic label development two-piece "electronic label proofing machine" ", "RFID electronic tag antenna laser proofing machine" has always been a key display product of Juxin IOT; it is particularly worth mentioning that an electronic tag detection machine has been added to the products displayed this time.

In the past two years, Juxin Internet of Things has locked in a major direction for its efforts: to supplement the functional deficiencies of the electronic label inspection machine software in the industry, and to promote the standardization of electronic label inspection machines, and then towards customization. This is mainly because with the increase of electronic label application scenarios, the requirements for data are becoming more and more detailed, and the software and hardware must meet the needs of customers and make progress together with customers.

Cheng Mingming told reporters that he had entered the field of electronic tags as early as 2005, mainly involving packaging equipment for electronic tags. In his career in the industry for more than ten years, he has witnessed the rapid development of electronic tags in the fields of new retail, books, and footwear. The industry has continuously put forward higher performance requirements for tags, and the functional requirements of label products have become more and more detailed. Therefore, the idea of being an expert in RFID electronic tag full life cycle testing equipment was born.

After the company has clarified this direction, it has continuously increased its investment in personnel and technology research and development, and upgraded and iterated test equipment involving electronic tags to meet the ever-increasing application requirements. In order to upgrade the testing equipment to a higher level, Juxin IOT has cooperated with domestic universities to conduct joint research and development, and provide some supporting technical support for the company's testing equipment. In addition, the company also cooperates with some foreign high-level testing equipment companies to supplement the deficiencies in precision testing equipment. At the same time, a lot of testing software personnel have been added to meet different testing requirements.

In the field of RFID testing applications, the most frequent testing is the development process testing of new products. This is a process of satisfying the project from scratch. The most effective way to improve efficiency is to have suitable testing equipment and testing tools. Cheng Mingming mentioned that while Juxin IoT provides testing equipment, it will also provide assistance for partners' temporary testing needs.

At present, the core products of Juxin IoT have applied for invention patents and utility model patents, as well as the copyrights of a number of test software. The test equipment has passed the actual application verification of customers, and has been continuously improved, and standardized products have been formed, and the relevant standards involving electronic tags have been completed with customers to promote the development of industry applications.

In recent years, with the assistance of Shenzhen Institute of Standards and Technology and Shenzhen Internet of Things Industry Association, Juxin IoT has drafted test equipment standards for some industries. Cheng Mingming said frankly that this process is very difficult. The civil development of electronic tags has gone through more than 20 years, and there are very few standards related to testing. Except for some standard tests on the protocol, they have been blank in other aspects. There is a lot of work to be done.