Call Us Now

+8615914489090

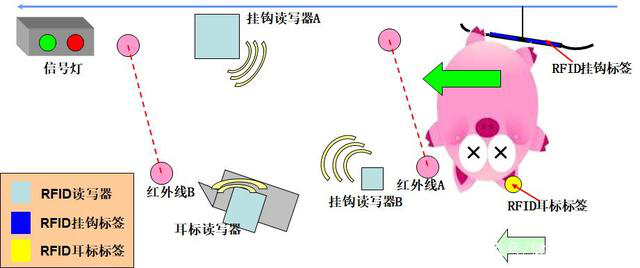

The reader reads the information of the hook and the ear tag, and associates the information of the ear tag to the hook. Attach electronic tags on both the front and back of the hook to ensure that the RFID reader can read the hook tags correctly.

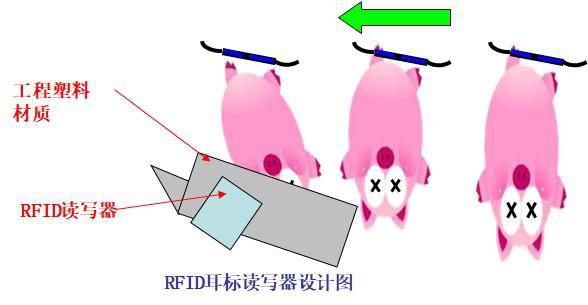

In the design of the RFID ear tag reader, the shell of the ear tag reader is V-shaped, so that the pig's head can be fully attached to the ear tag reader, and the read and write rate of the ear tag RFID tag is guaranteed to the greatest extent. The shell is made of ABS plastic to minimize interference. The RFID reader is hidden at the highest point on the back of the V-shaped housing.

This design solves the problem of antenna placement caused by the size difference of individual pigs. Keep the distance between the ear tag and the antenna within 30cm. Avoid the antenna from being damaged by collision.

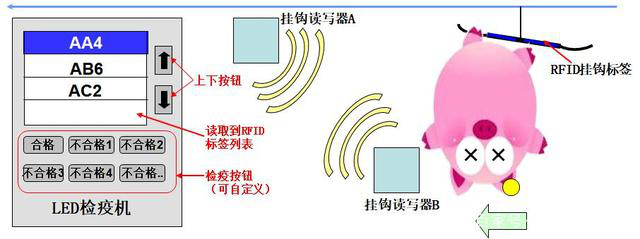

2. Entry of quarantine information

When the hook passes through the hook reader in the quarantine process, the reader reads the data on the hook and automatically adds it to the RFID tag list of the LED quarantine machine. The quarantine personnel transmits the quarantine result to the RFID hook label through the quarantine button of the LED quarantine machine. (Note: There are two quarantine times, one visceral quarantine, and one white bar quarantine. The operation steps for the two inspections are the same on the LED quarantine machine.)

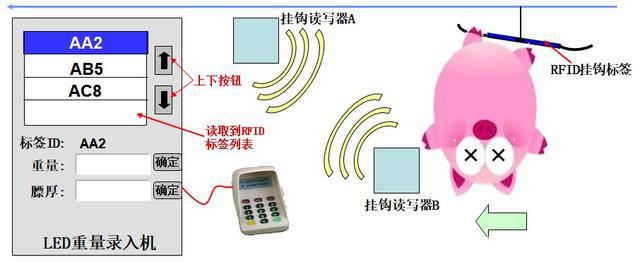

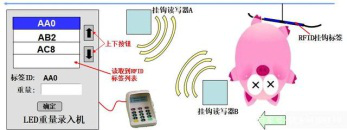

3.weighing information input

When the hook passes through the hook reader in the weighing process, the reader reads the data on the hook and automatically adds it to the list of RFID tags entered by the LED weight. The operator can automatically obtain the weight through the weighing machine, or input the weight through the small keyboard. The operator uses the small keyboard to input fatness information. Click OK to complete the LED weight entry machine.

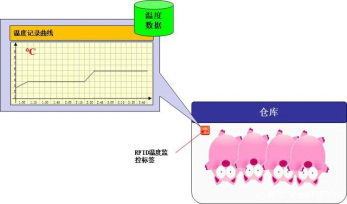

4. Real-time recording of cold storage temperature information

Through the RFID temperature monitoring tag, the temperature change of the cold storage can be monitored in real time, and the change information can be transmitted to the RFID reader in real time, and then transmitted to the background information system, and the staff can see the temperature change in real time.

5.weighing out of the library information input

When the hook passes through the hook reader in the weighing process, the reader reads the data on the hook and automatically adds it to the list of RFID tags entered by the LED weight. The operator can automatically obtain the weight through the weighing machine, or input the weight through the small keyboard. Click OK to complete the LED weight entry machine.

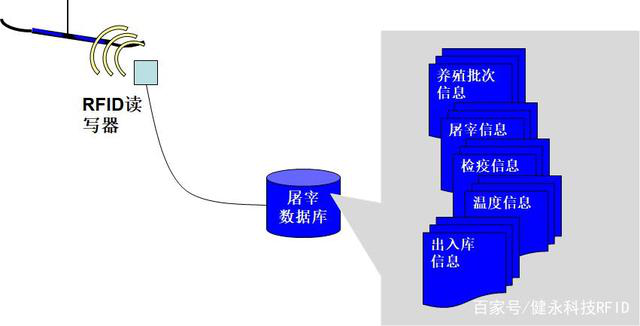

6. RFID and back-end database information transfer

The label information sent by the RFID read by the RFID reader in each link will eventually be transmitted to the back-end database, thereby forming a complete slaughter, quarantine, storage, and outbound information database.

to sum up

The application of RFID readers in the pork slaughtering process can ensure the accuracy and traceability of information, and can effectively establish a pork traceability system.